Q&A

-

Q: Machine Printable Water-Base Ink?.

A:

Aqua EV Clear & Aqua EV White, White(W8)-high mesh count

Specialty- slow drying, super soft, elastic, non-tacky, machine printable, high durability........

-

Q: How to stop dye bleeding polyester fabric?.

A:

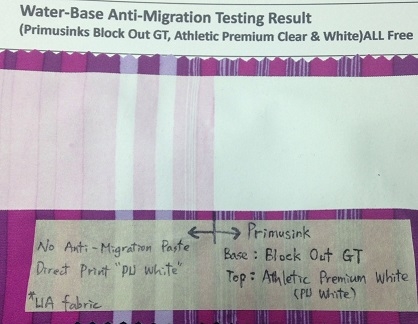

While printing on dyed problem polyester fabric, there is always a major problem to see migration or bleeding issue either after curing.

Without curing, even migration comes up after a period of time. To solve the problem, Primusinks Block Out GT is the best solution to entirely stop bleeding or migration from polyester.

-

Q: How to obtain high washing durability on foil print?.

A:

Primusinks Bond GT-70NY is a 100% PU based glue adhesive for high durable property on washing. It is one product for all types of heat transfer, such as foil, flock paper and static flock dust.

Washing Parameter: 30C x 10 cycles, 2 hours/cycle, inside-out

-

Q: How to obtain the highest wet rubbing fastness on water based rubber?.

A:

Wet rubbing is always an issue particularly with "Matt" rubber paste in deep colors. This video shows Primus Fixer W-9140 enhance both dry and wet rubbing fastness upto 4.5 grade. See the video link.

-

Q: How to avoid screen blocking while applying inks on automatic printing machine?.

A:

First of all, the printing inks should be slow drying type of rubberized paste, or so called machine rubber, for a proper and adequate handling on production. Our Aqua EV Series is the best for machine running.

Secondly, it is always a wise action to add "Primusinks Add. Retarder" to increase paste itself dwell time on machine to maximize productivity, since from time to time the working condition would be varied by weather/season/humidity, etc.

-

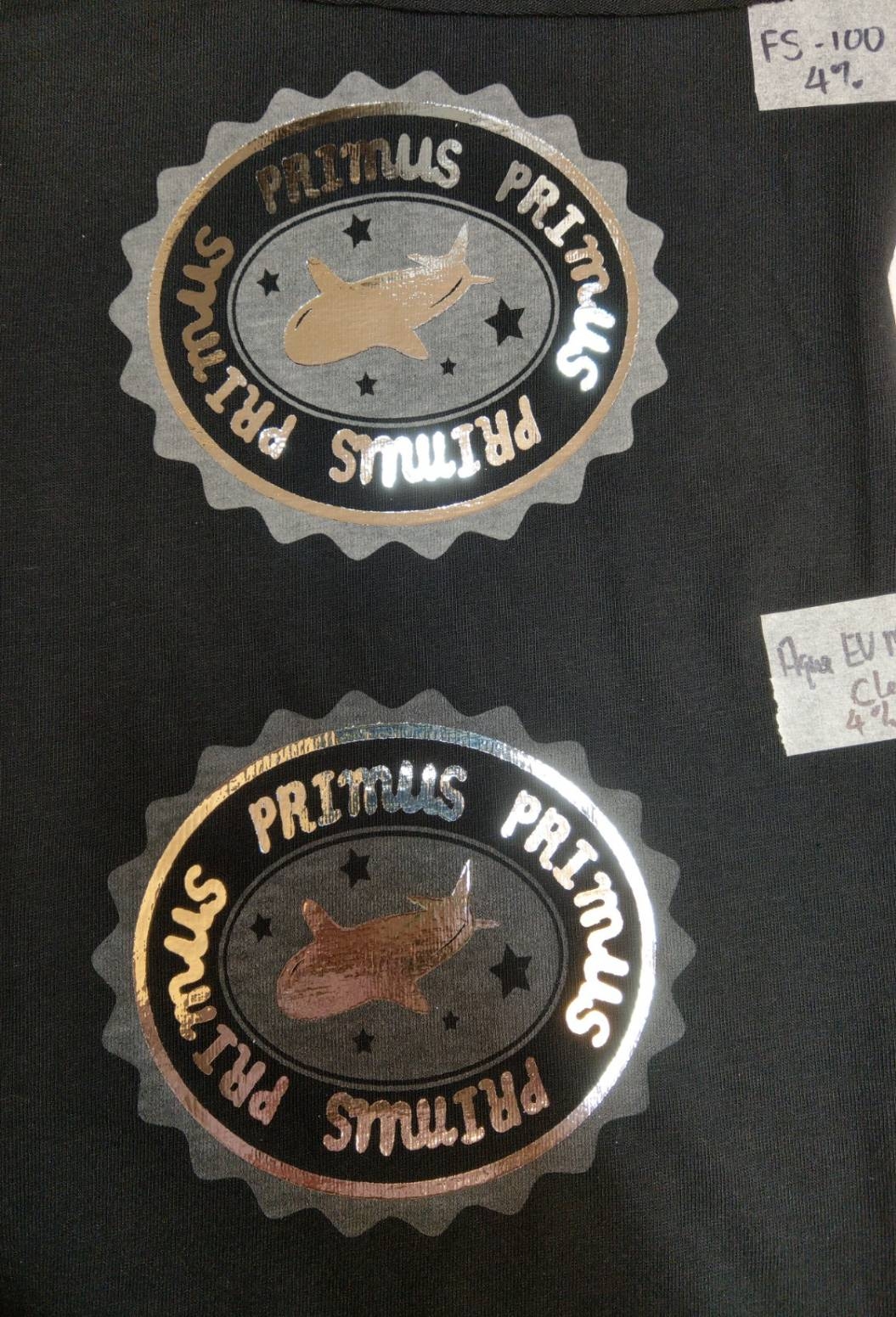

Q: How to prevent Foil Stain-Free In Water Based Inks?.

A:

First of all, those water based inks must mixed with Primusinks Xlinker TS-750. For examples, all water based clear series should add on 4% of Primusinks Xlinker TS-750 and all water based white series should be added 2% of Primusinks Xlinker TS-750.